Cleaner Air For Your Crew: Why An Air Purifier For Factory Settings Is A Smart Move

Think about the air inside your factory. Is it as fresh and clean as it could be? For many industrial places, the air often holds tiny bits, smells, and even invisible germs that can cause trouble. Getting an air purifier for factory spaces is not just a nice idea; it's a really important step for everyone who works there and for the whole operation. It’s about making sure the air your team breathes is good, which, you know, makes a big difference.

Keeping the air clear in a factory is a bit more involved than just opening a window, as a matter of fact. Industrial settings have unique challenges, from dust and fumes to chemicals and even tiny airborne things that can cause problems. Ignoring these air quality issues can lead to various difficulties, both for the people working hard every day and for the machines that keep everything running. So, understanding how to improve this environment is pretty key.

This discussion will walk you through why factory air matters so much, what kinds of air purifiers are out there for these big spaces, and how picking the right one can bring a lot of good things to your business. We'll look at the different kinds of things air purifiers can catch and how they help keep your place productive and your people feeling better, too it's almost a given.

Table of Contents

- Why Factory Air Quality Matters

- What Are Air Purifiers for Factories?

- Choosing the Right Air Purifier for Your Factory

- Benefits of Investing in Factory Air Purification

- Real-World Applications and Success Stories

- Maintenance and Longevity

- Frequently Asked Questions

Why Factory Air Quality Matters

The air quality in a factory is a pretty big deal, honestly. It’s not just about comfort; it truly impacts the well-being of your staff and the smooth running of your operations. When the air is full of unwanted stuff, it can cause all sorts of problems that might not be immediately obvious, you know. Good air is just a fundamental part of a good workplace, basically.

Health of Your Workforce

When people breathe in dusty or chemically-laden air all day, every day, it can really start to affect their health. Think about tiny bits floating around from manufacturing processes, or maybe even fumes from certain materials; these things can irritate lungs, cause allergies to flare up, or even lead to more serious, long-term health issues for your team. A lot of these airborne particles, even those as small as 0.03 microns, are invisible but can cause trouble, so it's almost like a hidden danger. Providing cleaner air shows you care about your employees, and that, in a way, builds trust and loyalty.

Poor air can also lead to more sick days, which means less people on the floor and potential delays in getting work done. When staff members are feeling unwell because of the air they're breathing, their focus and energy levels can drop, naturally. This isn't good for anyone, and it’s a situation that can be avoided with the right air cleaning solutions. It’s pretty clear that healthy workers are happier and more productive workers, you know.

Protecting Equipment and Products

It’s not just people who suffer from bad air quality; your expensive machinery and even the products you make can take a hit, too. Dust and fine particles can get into sensitive equipment, causing wear and tear, and leading to breakdowns or requiring more frequent maintenance. This means unexpected costs and downtime, which no factory wants, you know. Clean air helps keep your valuable assets running smoothly, and that's a really good thing for your bottom line.

For some factories, airborne contaminants can also affect the quality of the products being produced. Imagine a place where electronics are made; even a tiny speck of dust could mess up a delicate circuit. Or perhaps a food processing plant where cleanliness is absolutely critical. Air purifiers help keep the production environment pristine, protecting your output and maintaining your quality standards, which is very important. This means fewer defects and a better reputation for your goods, basically.

Meeting Regulatory Standards

Governments and industry bodies often have rules about the air quality in workplaces, especially in industrial settings. These rules are there to protect workers and the surrounding environment, as a matter of fact. Not meeting these standards can lead to fines, legal issues, and a damaged company image. Keeping up with these rules means having systems in place that actively clean the air, you know.

Staying on the right side of these regulations is a bit like playing by the rules of the game. It shows you're a responsible business and helps avoid any unnecessary problems down the road. Investing in an air purifier for factory operations helps you meet these requirements, giving you peace of mind and ensuring your business runs without unnecessary interruptions. It’s a good way to stay ahead and keep things above board, obviously.

What Are Air Purifiers for Factories?

When we talk about an air purifier for factory use, we’re looking at something much more substantial than the small units you might have in your home. These are tough, powerful machines built to handle the unique and often heavy-duty air challenges found in industrial settings, you know. They are designed to manage a wide range of airborne problems, from fine dust to chemical fumes, and that's a big difference.

Beyond Home Units

Home air purifiers are great for catching pet dander or pollen in a living room, but a factory environment presents a whole different set of problems. Industrial spaces often have much larger volumes of air to clean, and the types of pollutants are often more concentrated and more harmful. We're talking about things like welding fumes, sawdust, chemical vapors, or even airborne viruses that need a much more robust solution. A factory needs a system that can continuously handle these tough conditions, so it's a different league entirely.

Manufacturers like Guangzhou Olansi Healthcare Co., Ltd., which has been around since 2009 focusing on health and environmental protection equipment, understand these differences. They, and others like China Loong Air Purifier Co., Ltd., or Hoko Air Purifier Factory, specialize in creating solutions that are built to last and perform in demanding industrial settings. These are not just bigger versions of home units; they are engineered for industrial strength, you know, and that's a critical distinction.

Key Technologies at Work

An effective air purifier for factory environments uses a combination of different technologies to tackle various kinds of air problems. One of the most common and effective is the True HEPA filter. These filters are really good at catching very tiny particles, like dust, pollen, mold spores, and even airborne pollutants as small as 0.03 microns in size, which is very impressive. They are a core part of many industrial air cleaners, as a matter of fact.

Another important component is the active carbon filter. These are excellent for removing odors, gases, and chemical fumes that HEPA filters might miss. Many industrial air cleaners, including those from companies like Camfil, use carbon filters alongside HEPA filters to provide a really comprehensive cleaning solution, you know. This combination is particularly effective for places with strong smells or chemical processes.

Some industrial air purifiers also use other technologies. Negative ion generators can help clump small particles together so they fall out of the air or are more easily caught by filters. UV sterilizers, often seen in products from Suzhou Hanbang Sterilizer Equipment Co., Ltd., are used to kill airborne viruses, bacteria, and other microorganisms, which is particularly relevant for health-sensitive environments. These different technologies work together to create a much cleaner and safer air space, basically, and that's a good thing for everyone.

Choosing the Right Air Purifier for Your Factory

Picking the right air purifier for factory use isn't a one-size-fits-all kind of decision. It really depends on what your factory does, what kind of things are in the air, and how big your space is. Thinking through these points carefully will help you find a system that truly works for your specific needs, you know, and that's pretty important.

Assessing Your Specific Needs

Before you even start looking at models, you need to figure out what kind of air problems you have. Are you dealing mostly with fine dust from woodworking or machining? Or are chemical fumes and strong odors the main issue? Perhaps it's about keeping airborne viruses in check, especially in today's world. Knowing your primary pollutants helps you choose the right filter types and technologies, you know. You might even need to do an air quality assessment to get a clear picture of what's floating around, which is often a smart first step.

Also, think about the size of the area you need to clean. A small workshop will have different requirements than a vast production floor. The volume of air that needs to be processed, often measured in cubic feet per minute (CFM) or cubic meters per hour (CMH), is a key factor in selecting a purifier with enough power. You also need to consider how often the air needs to be exchanged or cleaned in that space, as a matter of fact. All these details help narrow down your choices, basically.

Different Types for Different Pollutants

As we talked about, different pollutants need different solutions. For very fine particles like welding smoke or manufacturing dust, a system with a strong True HEPA filter is usually the way to go. These filters are incredibly effective at capturing tiny bits that can cause respiratory problems, you know. They are a must-have for environments with a lot of particulate matter.

If your factory produces strong smells, gases, or volatile organic compounds (VOCs) from paints, solvents, or other chemicals, then an air purifier with a robust active carbon filter is absolutely necessary. These filters absorb odors and chemical vapors, neutralizing them rather than just catching them. For environments where airborne pathogens are a concern, like food processing or medical device manufacturing, adding UV-C light sterilization can provide an extra layer of protection, you know. It’s about matching the tool to the task, really.

Considering Manufacturer Expertise

When you’re looking for an air purifier for factory use, it’s a good idea to partner with manufacturers who really know their stuff. Companies like Guangzhou Olansi Healthcare Co., Ltd., which has over 14 years of experience in the air purification industry, or Trumkey Technology with over 15 years, bring a lot of knowledge to the table. They understand the demands of industrial settings and can offer solutions that are proven to work, you know.

Many of these professional manufacturers, such as China Loong Air Purifier Co., Ltd., offer OEM/ODM services, meaning they can even create custom solutions for your specific factory setup. Finding high-quality air filters directly from a factory, like those mentioned for residential or commercial HVAC systems, can also be a cost-effective approach. Look for suppliers who guarantee high quality and stand by their products, as some even offer returns if clients are not satisfied, which is a good sign. Companies like Hoko Air Purifier Factory in China also have a large selection, so you might find what you need there. It’s about choosing a partner who can provide smart, efficient solutions for cleaner air in your industrial space, you know, and that's very important for long-term success.

Benefits of Investing in Factory Air Purification

Putting money into an air purifier for factory operations isn't just an expense; it's a really smart investment that pays off in many ways. The positive effects ripple throughout your entire business, making things better for everyone involved. It’s pretty clear that clean air brings a lot of good things, you know.

Improved Worker Well-being

When the air is clean, your employees feel better. They might experience fewer respiratory issues, less irritation in their eyes or throats, and generally just feel more comfortable during their workday. This leads to a happier workforce, which can reduce stress and improve overall morale. Giving your team a healthier place to work shows you value them, and that, in a way, is a huge benefit in itself. It’s about creating an environment where people can thrive, you know.

A more comfortable and healthier environment can also lead to fewer sick days and less time off for health-related issues. This means more consistent staffing and a more reliable workforce, which is really good for productivity. When your team feels good, they perform better, as a matter of fact. It’s a win-win situation for both the employees and the business, basically.

Enhanced Productivity

It might seem simple, but clean air actually helps people focus better. When employees aren't bothered by dust, fumes, or bad smells, they can concentrate more fully on their tasks. This can lead to fewer mistakes, higher quality work, and a faster pace of production. An air purifier for factory use helps create an environment where everyone can do their best work without unnecessary distractions or discomfort, you know.

Also, by protecting your equipment from airborne contaminants, you reduce the chances of unexpected breakdowns and costly repairs. When machines run smoothly and consistently, your production lines stay active, and you avoid delays. This directly translates to increased output and more efficient operations. It's a bit like keeping your tools sharp; clean air keeps your whole operation running at its peak, you know.

Long-Term Cost Savings

While there's an initial cost for an air purifier for factory installation, the savings over time can be quite significant. Think about reduced healthcare costs for employees due to fewer work-related respiratory issues. Then there's the money saved on equipment maintenance and repairs because dust and grit aren't clogging up machinery. These savings can really add up, you know.

Furthermore, avoiding fines and legal troubles from not meeting air quality regulations is a big financial benefit. A cleaner environment can also lead to less product spoilage or defects, which saves on waste and rework. Some suppliers, like Factory Direct Filters, offer filter subscriptions that can help you save even more on replacement parts, making ongoing costs more manageable. In the long run, the investment in good air quality often pays for itself, and then some, basically.

Real-World Applications and Success Stories

An air purifier for factory settings isn't just a theoretical idea; it's a practical solution used across many different types of industrial spaces today. From bustling manufacturing lines to quiet storage areas, the need for cleaner air is pretty universal, you know. The applications are really quite varied, as a matter of fact.

From Manufacturing to Warehousing

In a manufacturing plant, where processes might create a lot of dust from cutting, grinding, or sanding, or fumes from welding or chemical treatments, industrial air cleaners are absolutely vital. They capture these pollutants at the source or clean the ambient air, protecting workers and preventing buildup on machinery. For example, a professional Chinese air purifier factory like Guangzhou Olansi, known for its true HEPA air purifiers and active carbon filters, provides solutions ideal for these kinds of environments. Their experience in the water purification and air purification industry, spanning over 12 years, speaks to their understanding of these challenges, you know.

Even in warehouses, where products are stored and moved, dust can be a major issue. Forklifts can stir up particles, and packaging materials can shed fibers. An air purifier for factory warehouses helps maintain a cleaner environment, which is better for the health of the workers and also helps keep stored goods free from contamination. Industrial air cleaners are also ideal for removing odors, gases, and airborne viruses in various industrial settings, as Camfil's industrial air purifiers demonstrate with their use of carbon and HEPA filters. This makes them versatile tools for improving air quality wherever it's needed, basically.

Maintenance and Longevity

Just like any important piece of equipment, an air purifier for factory use needs some regular care to keep it working its best. Taking good care of your air purification system means it will last longer and continue to provide clean air efficiently, you know. It's pretty straightforward, but really important.

Keeping Your System Running Smoothly

The main thing to remember is to change or clean the filters regularly. Over time, filters get full of the particles they've captured, and when they're too full, they can't clean the air as well. The specific schedule for filter changes will depend on how much your factory uses the purifier and how dirty the air is, but manufacturers usually provide guidelines. Some purifiers, like certain Dyson models, even have filter indicators that tell you when it's time for a reset or replacement, which is very helpful. Keeping up with this simple task ensures your system always performs at its peak, basically.

Beyond filters, it’s a good idea to periodically check the system for any blockages or signs of wear. Making sure the fan and other moving parts are clean and working correctly helps prevent bigger problems down the line. Many modern industrial air purifiers come with automatic modes where the purifier can adjust the fan speed based on air quality, which can help optimize filter life and energy use. Regular, simple checks will help your air purifier for factory settings provide peace of mind and fresh air for many years to come, you know. Learn more about air quality solutions on our site, and for specific industrial applications, you can also look into this page .

Frequently Asked Questions

What kind of air purifier is best for a large factory space, you might ask?

For large factory spaces, industrial-grade air purifiers with powerful fans and multi-stage filtration systems are typically the most effective. These often combine True HEPA filters for fine particles and active carbon filters for gases and odors. The specific type really depends on the main pollutants present in your factory, as a matter of fact.

How often do filters in a factory air purifier need to be changed, you know?

The frequency of filter changes depends on the level of pollution in your factory and how many hours the purifier runs each day. In very dusty or fume-heavy environments, filters might need changing more often, perhaps every few months. For less polluted areas, they might last six months to a year. Your purifier's manufacturer will provide a recommended schedule, basically.

Can air purifiers help with chemical fumes in a factory, like?

Yes, absolutely. Air purifiers equipped with robust active carbon filters are specifically designed to absorb and neutralize chemical fumes, volatile organic compounds (VOCs), and strong odors. For certain chemical processes, a combination of carbon filtration and other technologies might be recommended to ensure comprehensive removal, you know. It’s a very common application for industrial air cleaners.

So, making the choice to get an air purifier for factory operations is a pretty big step towards creating a better, safer, and more productive environment. It’s about taking care of your people, protecting your valuable equipment, and making sure your business runs smoothly, as a matter of fact. The benefits, from healthier staff to better output, really show the value of clean air. It’s a smart move for any industrial setting looking to improve its overall well-being and efficiency, you know.

For more general information on workplace safety and air quality standards, you might find resources from the Occupational Safety and Health Administration (OSHA) quite helpful.

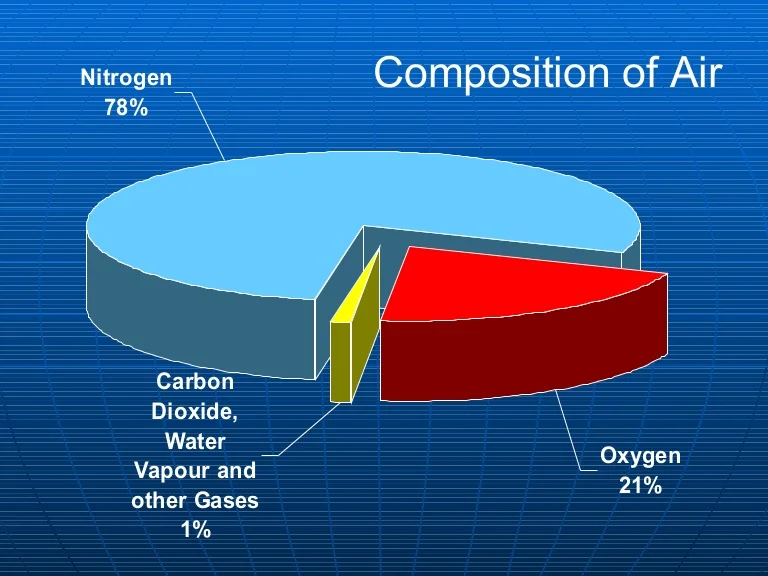

Composition Of Air

Aire - Wikipedia, la enciclopedia libre

Air